Background

From the earliest recorded history, humans have been fascinated by reflections. Narcissus was supposedly bewitched by his own reflection in a pool of water, and magic powers are ascribed to mirrors in fairy tales. Mirrors have advanced from reflective pools and polished metal surfaces to clear glass handheld and bathroom mirrors. They have been used in interior decoration since the 17th century, and reflective surfaces on cars and in hotel lobbies are still popular in modern design. Mirrors are used for practical purposes as well: examining our appearance, examining what is behind us on the road, building skyscrapers, and making scientific research instruments, such as microscopes and lasers.

The nature of modernn mirrors is not fundamentally different from a pool of water. When light strikes any surface, some of it will be reflected. Mirrors are simply smooth surfaces with shiny, dark backgrounds that reflect very well. Water reflects well, glass reflects poorly, and polished metal reflects extremely well. The degree of reflectivity—how much light bounces off of a surface—and the diffusivity of a surface—what direction light bounces off of a surface—may be altered. These alterations are merely refinements, however. In general, all reflective surfaces, and hence, all mirrors, are really the same in character.

Man-made mirrors have been in existence since ancient times. The first mirrors were often sheets of polished metal and were used almost exclusively by the ruling classes. Appearance often reflected, and in some cases determined, position and power in society, so the demand for looking glasses was high, as was the demand for the improvement of mirror-making techniques. Silvering—the process of coating the back of a glass sheet with melted silver—became the most popular method for making mirrors in the 1600s. The glass used in these early mirrors was often warped, creating a ripple in the image. In some severe cases, the images these mirrors reflected were similar to those we’d see in a fun-house mirror today. Modern glassmaking and metallurgical techniques make it easy to produce sheets of glass that are very flat and uniformly coated on the back, improving image clarity tremendously. Still, the quality of a mirror depends on the time and materials expended to make it. A handheld purse mirror may reflect a distorted image, while a good bathroom mirror will probably have no noticeable distortions. Scientific mirrors are designed with virtually no imperfections or distorting qualities whatsoever.

Materials technology drastically affects the quality of a mirror. Light reflects best from surfaces that are non-diffusive, that is, smooth and opaque, rather than transparent. Any flaw in this arrangement will detract from the effectiveness of the mirror. Innovations in mirror making have been directed towards flattening the glass used and applying metal coatings of uniform thickness, because light traveling through different thicknesses of glass over different parts of a mirror results in a distorted image. It is due to these irregularities that some mirrors make you look thinner and some fatter than normal. If the metal backing on a mirror is scratched or thin in spots, the brightness of the reflection will also be uneven. If the coating is very thin, it may be possible to see through the mirror. This is how one-way mirrors are made. Non-opaque coating is layered over the thin, metal backing and only one side of the mirror (the reflecting side) is lit. This allows a viewer on the other side, in a darkened room, to see through.

Raw Materials

Glass, the main component of mirrors, is a poor reflector. It reflects only about 4 percent of the light which strikes it. It does, however, possess the property of uniformity, particularly when polished. This means that the glass contains very few pits after polishing and will form an effective base for a reflective layer of metal. When the metal layer is deposited, the surface is very even, with no bumps or wells. Glass is also considered a good material for mirrors because it can be molded into various shapes for specialty mirrors. Glass sheets are made from silica, which can be mined or refined from sand. Glass made from natural crystals of silica is known as fused quartz. There are also synthetic glasses, which are referred to as synthetic fused silica. The silica, or quartz, is melted to high temperatures, and poured or rolled out into sheets.

A few other types of glass are used for high-quality scientific grade mirrors. These usually contain some other chemical component to strengthen the glass or make it resistant to certain environmental extremes. Pyrex, for example, is a borosilicate glass—a glass composed of silica and boron—that is used when mirrors must withstand high temperatures.

In some cases, a plastic substrate will do as well as a glass one. In particular, mirrors on children’s toys are often made this way, so they don’t break as easily. Plastic polymers are manufactured from petroleum and other organic chemicals. They can be injection molded into any desired shape, including flat sheets and circles, and can be opaque or transparent as the design requires.

These base materials must be coated to make a mirror. Metallic coatings are the most common. A variety of metals, such as silver, gold, and chrome, are appropriate for this application. Silver was the most popular mirror backing one hundred years ago, leading to the coinage of the term “silvering.” Old silver-backed mirrors often have dark lines behind the glass, however, because the material was coated very thinly and unevenly, causing it to flake off, scratch or tarnish. More recently, before 1940, mirror manufacturers used mercury because it spread evenly over the surface of the glass and did not tarnish. This practice was also eventually abandoned, for it posed the problem of sealing in the toxic liquid. Today, aluminum is the most commonly used metallic coating for mirrors.

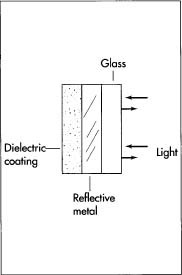

Scientific grade mirrors are sometimes coated with other materials, like silicon oxides and silicon nitrides, in up to hundreds of layers of, each a 10,000th of an inch thick. These types of coatings, referred to as dielectric coatings, are used both by themselves as reflectors, and as protective finishes on metallic coatings. They are more scratch resistant than metal. Scientific mirrors also use silver coatings, and sometimes gold coatings as well, to reflect light of a particular color of light more or less well.

Design

Surface regularity is probably the most important design characteristic of mirrors. Mirrors for household use must meet roughly the same specifications as window panes and picture frame glass. The glass sheets used must be reasonably flat and durable. The designer need only specify the thickness required; for example, thicker mirrors are more durable, but they are also heavier. Scientific mirrors usually have specially designed surfaces. These surfaces must be uniformly smooth within several lOOOths of an inch, and can be designed with a specific curvature, just like eyeglass lenses. The design principle for these mirrors is the same as that of eyewear: a mirror may be intended to focus light as well as reflect it.

The mirror design will also specify the type of coating to be used. Coating material is chosen based on required durability and reflectivity and, depending on the intended purpose of the mirror, it may be applied on the front or back surface of the mirror. Any subsequent layers of protective coatings must also be specified at this stage. For most common mirrors, the reflective coating will be applied on the back surface of the glass because it is less likely to be harmed there. The back side is then frequently mounted in a

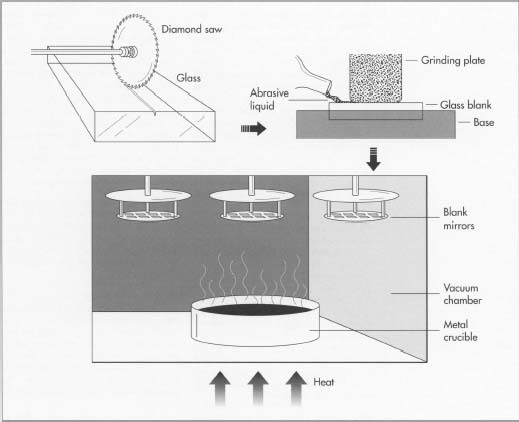

The initial step in mirror manufacture involves cutting and shaping the glass blanks. Cutting is usually done with a saw with diamond dust embedded in the tips. Next, the blanks are put in optical grinding machines, which use abrasive liquid plus a grinding plate to produce a very even, smooth finish on the blanks. The reflective material is then applied in an evaporator, which heats the metal coating until it evaporates onto the surface of the blanks.plastic or metal frame so as to entirely seal the coating from the air and sharp objects.

For scientific use, the color, or wavelength of light, which the mirror will reflect must be considered. For standard visible light or ultraviolet light mirrors, aluminum coatings are common. If the mirror is to be used with infrared light, a silver or gold coating is best. Dielectric coatings are also good in the infrared range. Ultimately, however, the choice of coating will depend on durability as well as wavelength range, and some reflectivity may be sacrificed for resilience. A dielectric coating, for example, is much more scratch resistant than a metallic coating and, despite the additional cost, these coatings are often added on top of metal to protect it. Coatings on scientific grade mirrors are usually applied on the front surface of the glass, because light which travels through glass will always distort to a small degree. This is undesirable in most scientific applications.

The Manufacturing

Process

Cutting and shaping the glass

- 1 The first step in manufacturing any mirror is cutting the outline of the glass “blank” to suit the application. If the mirror is for an automobile, for example, the glass will be cut out to fit in the mirror mount on the car. Although some mirror manufacturers cut their own glass, others receive glass that has already been cut into blanks. Regardless of who cuts the glass, very hard, finely pointed blades are used to do the cutting. Diamond scribes or saws—sharp metal points or saws with diamond dust embedded in them—are often used because the diamond will wear down the glass before the glass wears down the diamond. The cutting method used depends entirely on the final shape the mirror will take. In one method, the blades or scribes may be used to cut partway through the glass; pressure can then be used to break the glass along the score line. In another method, a machine uses a diamond saw to cut all the way through the glass by drawing the blade back and forth or up and down multiple times, like an automated bandsaw. Cutting is usually done before the metal coating is applied, because the coating may flake off the glass as a result of the cut. An alternative to cutting the glass to form blanks is to mold the glass in its molten state.

- 2 Blanks are then placed in optical grinding machines. These machines consist of large base plates full of depressions that hold the blanks. The blank-filled base is placed against another metal plate with the desired surface shape: flat, convex, or concave. A grinding compound—a gritty liquid—is spread over the glass blanks as they are rubbed or rolled against the curved surface. The action is similar to grinding spices with a mortar and pestle. The grit in the compound gradually wears away the glass surface until it assumes the same shape as the grinding plate. Finer and finer grits are used until the surface is very smooth and even.Hand grinding techniques exist as well, but they are extremely time-consuming and difficult to control. They are only used in cases where mechanical grinding would be impossible, as is the case with very large or unusually shaped surfaces. A commercial optical grinder can accommodate 50 to 200 blanks, which are all polished simultaneously. This is much more efficient than hand grinding. Even specialty optics can be made mechanically in adjustable equipment.

Applying the reflective material

- 3 When the glass surfaces are shaped appropriately and polished to a smooth finish, they are coated with whatever reflective material the designer has chosen. Regardless of the coating material, it is applied in an apparatus called an evaporator. The evaporator is a large vacuum chamber with an upper plate for supporting the blank mirrors, and a lower crucible for melting the coating metal. It is so called because metal is heated in the crucible to the point that it evaporates into the vacuum, depositing a coating on the surface of the glass much like hot breath will steam a cold window. Blanks are centered over holes in the upper plate that allow the metal vapor to reach the surface of the glass. Metals can be heated to several hundreds or thousands of degrees (depending on the boiling point of the metal), before they vaporize. The temperature and timing for this procedure are controlled very precisely to achieve exactly the right thickness of metal. This method of coating creates very uniform and highly reflective surfaces.

- 4 The shape of the holes in the upper plate will be transferred to the glass in metal, like paint through a stencil. This effect is often used to intentionally pattern the mirror. Metal stencils, or masks, can be applied to the surface of the glass to create one or more patterns.

- 5 Dielectric coatings—either as reflective layers or as protective layers over metal ones—are applied in much the same way, except that gases are used instead of metal chunks. Silicon oxides and silicon nitrides are typically used as dielectric coatings. When these gases combine in extreme heat, they react to form a solid substance. This reaction product forms a coating just like metal does.

- 6 Several evaporation steps may be combined to make a multiple-layer coating. Clear dielectric materials may be evaporated on top of metal or other dielectrics to change the reflective or mechanical properties of a surface. Mirrors with silvering on the back of the glass, for instance, often have an opaque dielectric layer applied to improve the reflectivity and keep the metal from scratching. One-way mirrors are the exception to this procedure, in which case great care must be taken not to damage the thin metal coating.

- 7 Finally, when the proper coatings have been applied, the finished mirror is mounted in a base or packed carefully in a shock resistant package for shipping.

Quality Control

How good does a mirror have to be? Is it sufficient to have 80 percent of the light bounce off? Does all 80 percent have to bounce in exactly the same direction? The answer is dependent on the application. A purse mirror might only be 80 or 90 percent reflective, and might have some slight irregularity in the thickness of the glass (like ripples on the surface of a pond). The image would be slightly distorted in this case, but the distortion would be barely visible to the naked eye. If, however, a mirror is to be used for a scientific application, for example in a telescope, the shape of the surface and the reflectivity of the coating must be known to a very specific degree, to insure the reflected light goes exactly where the telescope designer wants it, and at the right intensity. The tolerances on the mirror will affect the cost and ease with which it can be manufactured.

Batch mirror uniformity is the first and fore-most job of quality assurance. Mirrors on the edge of a grinding plate or evaporator chamber may not have the same surface or coating as those in the center of the apparatus. If there is a wide range of metal thicknesses or surface flatnesses in a single batch of mirrors, the process must be adjusted to improve uniformity.

Several methods are employed to test the integrity of a mirror. The surface quality is examined first visually for scratches, unevenness, pits, or ripples. This can be done with the unaided eye, with a microscope, or with an infrared photographic process designed to show differences in metal thicknesses.

For more stringent surface control, a profile of the mirror can be measured by running a stylus along the surface. The position of the stylus is recorded as it is dragged across the mirror. This is similar to the way a record player works. Like the record player, the drawback to a mechanical stylus is that it can damage the surface it is detecting. Mirror manufacturers have come to the same solution as the recording industry: use a laser. The laser can be used for non-destructive testing in the same way a compact disc player reads the music from a disc without altering its surface.

In addition to these mechanical tests, mirrors may be exposed to a variety of environmental conditions. Car mirrors, for example, are taken through extremes of cold and heat to

A typical mirror can include a metal reflective layer and one or more dielectric coatings—as protective layers over the metal one. Dielectric coatings are applied in much the same way as metal layers, except that gases such as silicon oxides and silicon nitrides are used instead of metal chunks.insure that they will withstand weather conditions, while bathroom mirrors are tested for water resistance.

The Future

As glassmaking techniques improve, mirrors find a more elaborate place in art and architecture. Stronger, lighter glasses are more attractive to designers. Some one-way mirror manufacturing techniques allow windows to be manufactured that are mirrored on the outside. This creates a distinctive appearance on a building and also makes the building’s air conditioning system more efficient by deflecting heat during the summer. This type of mirror is now commonly seen on office buildings.

Mirrors will also continue to be used in sophisticated optical applications, from microscopes and telescopes to laser-based reading systems such as compact disc players and bar code scanners.

Where To Learn More

Read more: http://www.madehow.com/Volume-1/Mirror.html#ixzz7gQbEcZMJ